6 Steps to Get Your Custom Hair Brush

1. Injection Molding

The products are selected in line with the production of high-quality process molds, materials, and customized colors. After seven years of crafty and meticulous processing, JUNYI makes professional customized brush injection shell for customers.

2. Painting

According to the different needs of customers, we choose different types of paint and spray brush surface to make different appearances and achieve perfect effects. JUNYI has more than 150 professional production workers and is committed to creating first-class hairbrushes to make customers satisfied.

3. Flocking

We use professional flocking machines to implant different chosen materials of hairbrush teeth into hairbrush shells. Every hairbrush tooth accesses the hole finely and it is tenacious.

4. Dyeing the Head

Choose different colors of epoxy resin to dye the head of hairbrush teeth to match the design and form a massage effect.

5. Printing

We master professional different printing techniques. Contact us to choose different printing methods to customize your own pattern design or logo.

6. Packaging

JUNYI adheres to the original intention of customer first and quality first to provide customers with excellent service. We offer different packaging formats of packaging products for customers to choose from, you can also customize your box label.

CUSTOMIZATION

LOGO

Custome logo to increase the brand recognition and awareness of your product and services.

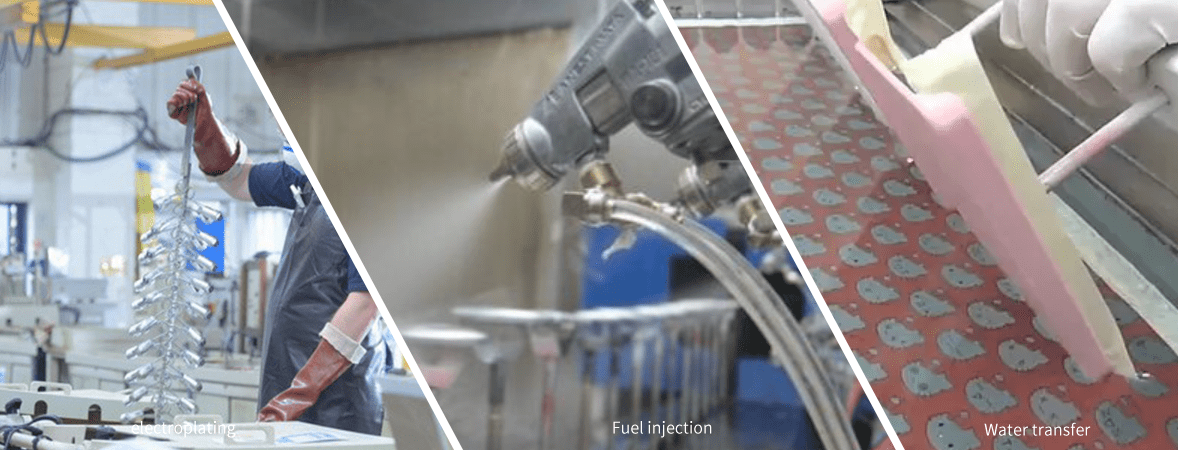

SURFACE TREATMENT PROCESS

Create your own brush style. Electroplanting, fuel injection,water transfer/thermal transfer printing

MATERIAL

Different materials have different properties. ABS, PP, PS, silicone, wooden, bamboo, wheat straw.... With hard, soft, environmental and more different features.

BRISTLES

Respond to demands for different hairstyles. Detangling, heat resistant. Nylon, TPEE, boar bristles, wooden, steel pin, sisal bristles.

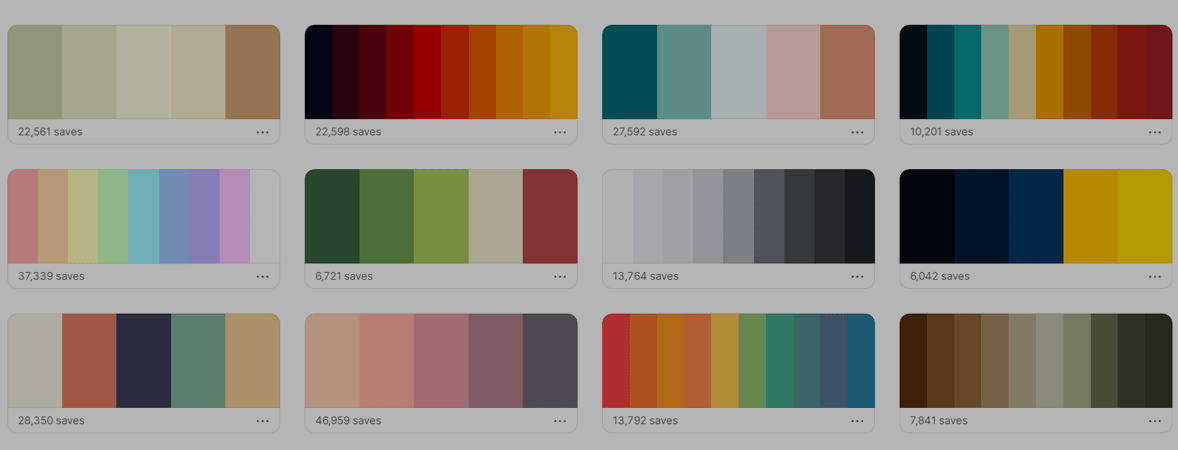

COLOUR

PANTONE color values can be customized.

CONTACT US

WE WOULD LOVE TO HEAR FROM YOU